Necessity & Benefits:

LEAN & Automated Production Line Design for both new production line design and old production line optimization is an effective way to improve production line productivity and efficiency, improve production transparency and quality and reduce the quantity of workers on the production line. LEAN & Automated Production Line Design is divided into two parts: LEAN design and Automation design. LEAN must be prior to Automation. Without LEAN analysis and design, the advantages of automation will not work, which might lead to the failure of automation investment. LEAN analysis and design is an essential part of LEAN & Automated Production Line Design.

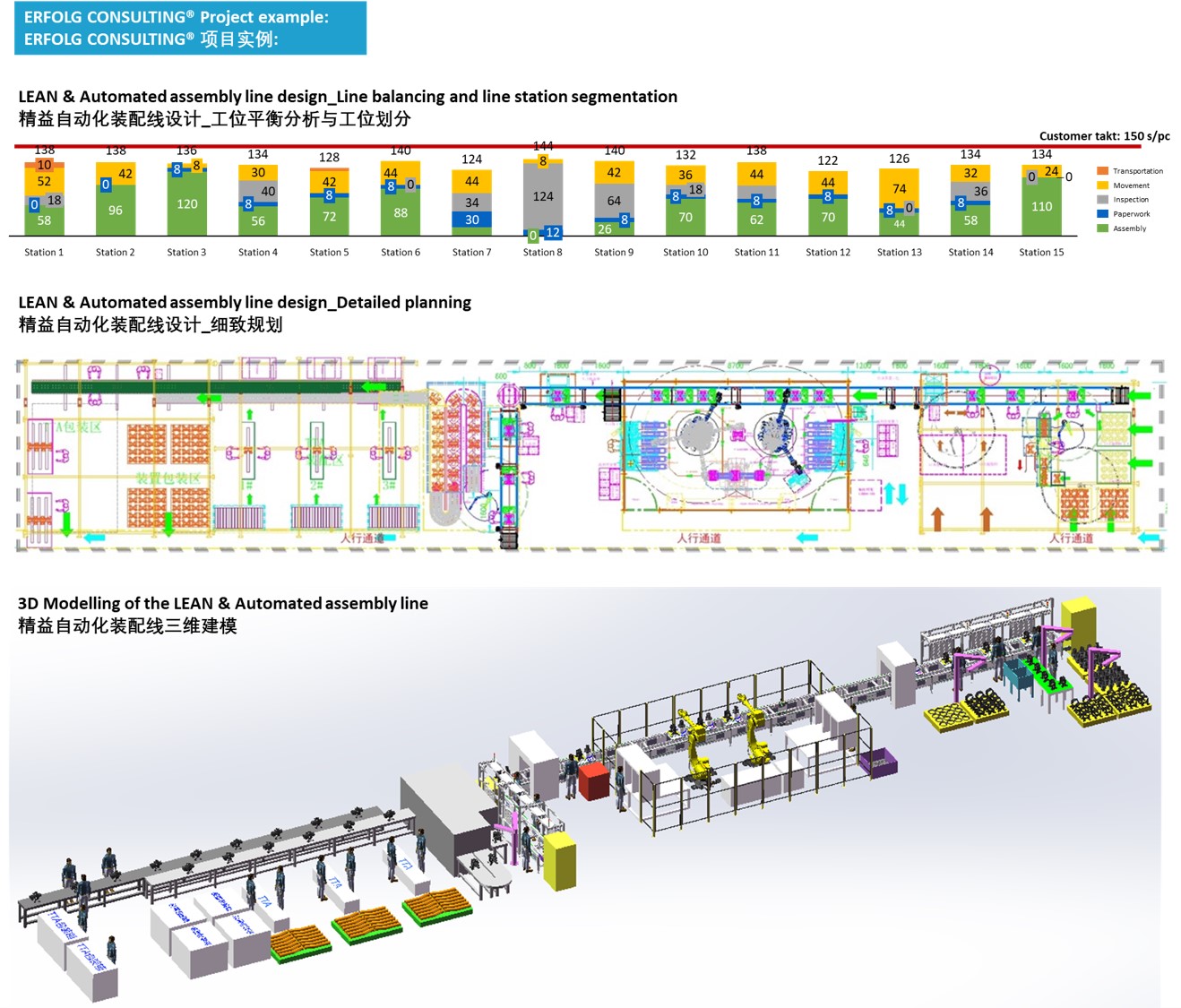

ERFOLG CONSULTING® uses its systematic LEAN & Automated Production Line Design method to help clients in various industries successfully design and implement LEAN & Automated production lines, which has achieved project targets and expected return on investment.

The systematic LEAN & Automated Production Line Design by ERFOLG CONSULTING® can help you achieve significant, quantifiable and sustainable benefits:

> Improvement of production productivity and efficiency

> Shortening of production through-put time

> Reduction in the number of workers on the production line

> Product quality improvement from the production line

> Transparency increase of the production line processes

Our professional consulting services:

The experts of ERFOLG CONSULTING® have helped more than 20 leading multinational corporations and domestic companies successfully design and implement LEAN & Automated production lines. We provide complete consulting services in the field of LEAN & Automated Production Line Design, from LEAN analysis and design to automation use cases identification, till the detailed design of LEAN & Automated Production Design. Besides, we provide 3D modelling & simulation of the design and implementation support to ensure the successful implementation of the project as planned.

Our services in the field of LEAN & Automated Production Line Design include:

1. LEAN analysis and design

▷ Product and production capacity planning, customer takt and production line takt calculation

▷ Production process analysis and optimization

▷ Production process time observation and ECRS analysis

▷ Production line balance analysis and workstation definition

▷ Identification and evaluation of automation use cases

2. Automation analysis and design

▷ Evaluation and selection of automation process, process time, efficiency, cycle time, etc.

▷ Detailed automation process analysis and design

3. Detailed planning of LEAN & Automated production lines

▷ Detailed planning of LEAN & Automation tools, tooling, material containers, etc. for the production line

▷ PFEP analysis and line-feeding concept development

▷ Detailed layout planning of the LEAN & Automated production line

▷ 3D modeling of the LEAN & Automated production line

4. Simulation & Verification of the LEAN & Automated production line design

5. Project management during the implementation phase

6. Production ramp-up support after the implementation of the LEAN & Automated production line